Those who visited RUVAS jewelry production are unlikely to doubt that the company's specialists really have golden hands. And not only in the figurative sense of the word.

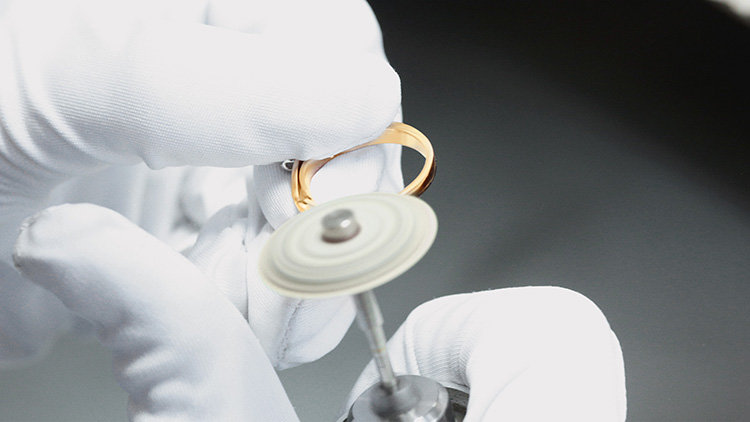

After the tumbling step, complex jewelry is sent to the mounting site. Here experts have to do really jewelry work. This is one of the most important stages of production, which includes several processes.

Cutting

Before proceeding directly to the mounting, the product must be sawed.

The sawing process is a painstaking process, and it takes place behind a workbench. The finale is mounted in the workbench cell - a very hard wood block in the form of a wedge, to which the product is pressed. The wizard manually adjusts the shape of the decoration using the file.

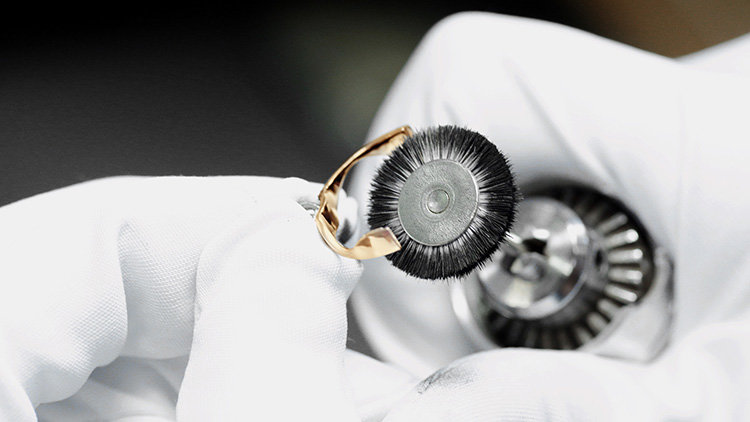

Along with manual, mechanical filing is used, through which difficult-to-reach areas of products are processed: slotted notches or internal surfaces of hollow articles.

Fit the size

This procedure is the exclusive of the rings.

The formation of the desired size is performed with the aid of a kayank (small hammer) and a crossbar, or a ring-gauge - a metal cone with divisions, denoting the dimensional row.

The eraser constantly checks with the ring gauge to properly "get in size". After fitting, the tire is aligned with the help of a nadfile - a small file for fine work.

Assembly

It is the assembly and is the key point in the mounting. At this stage complex products consisting of several components are assembled. For example, here the pendants are attached "eyelet" - a ring with which the jewelry is worn on the chain, the complex bracelets are connected and many other painstaking operations are performed.

Connection with a pin

Few people know that the earrings are cast separately from the decorative part of the product. It is the mounters that connect the movable and fixed elements of the lock.

The pin joint is created by accurately fitting the parts to each other and fastening them with a wire through a special hole. After binding, the wire is "flattened" from two sides, so that the "staves" are formed.

It is very important to choose the correct diameter of the hole and wire, so that the fastening and unfastening of the earring is as comfortable and reliable as possible.

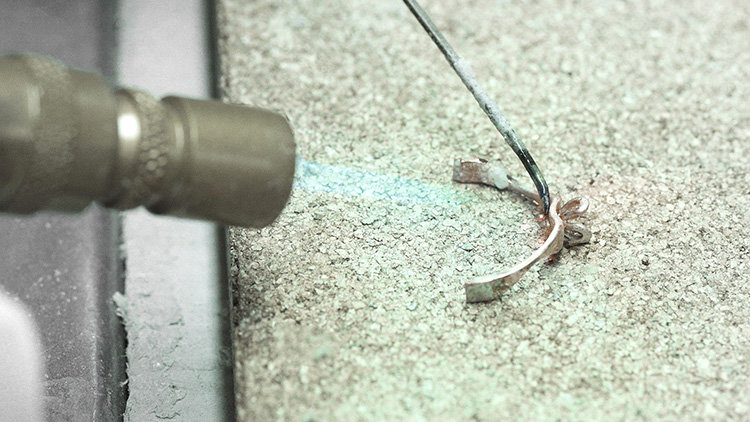

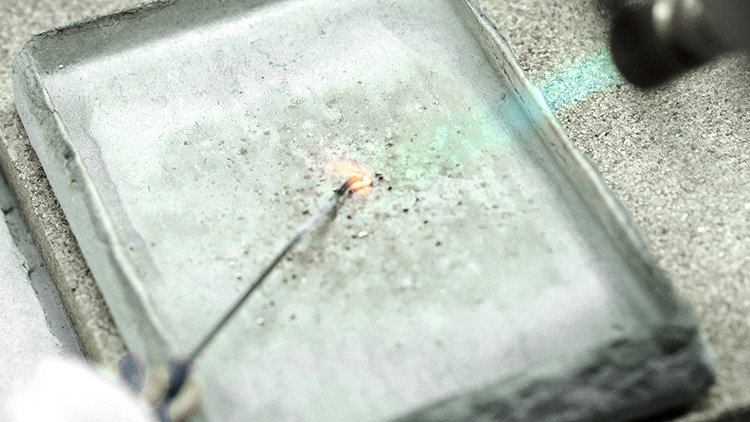

Soldering

Soldering, as a rule, is necessary in order to fasten on the products various decorative pads and join together the complex elements of jewelry. At this stage, the jeweler needs to show the maximum precision and skill. In the case of even a slight deviation from the process, the product will be spoiled.

It is very important to choose the correct melting temperature (distance to open flame) and adjust the burner to avoid a large flame.

After soldering, the master needs to carefully clean the traces of solder and trim the parts, if suddenly there was such a need.

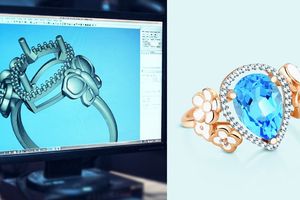

Laser welding

To obtain a non-removable connection of the decoration parts, the laser welding process is performed. This technology is implemented on high-tech equipment in order to create point connections. In this case, the metal melts in different parts of it under the action of laser radiation. Due to the crystallization and melting of metals, a pure compound is obtained, practically without a welding seam. The diameter of the beam can be adjusted to 0.3 mm - literally "solder the hair to the hair."

After mounting, the product acquires a complete look and is sent to the Verkhne-Volzhskaya inspection of assay supervision. There, the decoration is subjected to a thorough analysis, after which the product is put a sample of precious metal and the manufacturer's name.